Achieve World-Class Quality with Top Efficiency.

By providing the highest performing furnace equipment and the world’s leading software for strip annealing shop operation, RAD-CON facilities achieve the combination of high quality and low operating costs that provide a true competitive edge.

RAD-CON is not only a leading global producer of 100% hydrogen bell-type annealing furnaces (BAF) for strip and sheet coils, but also the leader in software for managing the annealing production process. RAD-CON provides:

- Design, equipment, and installation of 100% Hydrogen BAF.

- Facility sizes ranging from 10,000 t/y to 1,000,000 t/y.

- Software systems that use thermal models to manage the entire annealing operation.

Why are software models important to operating an annealing shop, 100% H2 or traditional HN? Click Here

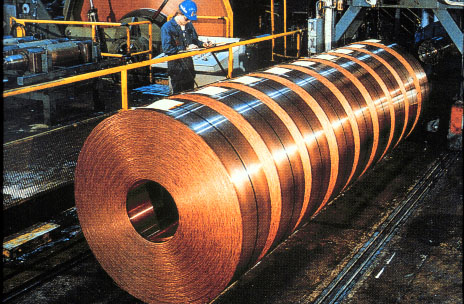

Typical Strip Products Annealed

in RAD-CON equipment:

- Low & High carbon steels

- High strength steel

- Steels for tin plating

- Stainless steel

- Copper, Brasses, Bronzes, and other copper-based alloys

- Aluminum alloys

Industries Served by RAD-CON:

- Automotive

- Construction

- Industrial

- Electrical

- Energy